Host

Suspendisse tristique vehicula ante tortor, ut auctor diam ornare ut. Pellentesque et ex et dolor tempor suscipit. Phasellus vel orci vel orci tincidunt interdum. Nunc quis viverra metus. In cursus tincidunt. Nam consequat nibh justo, non sollicitudin sem placerat vitae.

Client & task

Suspendisse tristique vehicula ante tortor, ut auctor diam ornare ut. Pellentesque et ex et dolor tempor suscipit. Phasellus vel orci vel orci tincidunt interdum. Nunc quis viverra metus. In cursus tincidunt. Nam consequat nibh justo, non sollicitudin sem placerat vitae.

Objectives

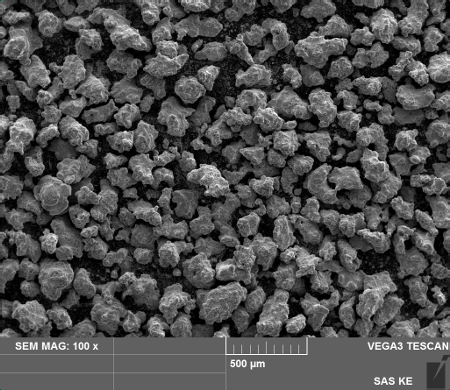

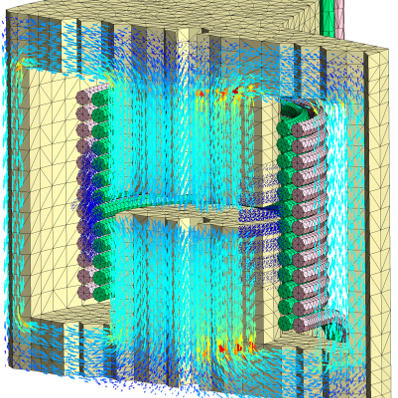

Power converters for high-power and high-frequency applications increasingly demand inductors and transformers that are smaller, lighter, and more thermally robust. Achieving such compactness requires a departure from conventional manufacturing techniques. Emerging fabrication methods—such as 3D printing of magnetic structures, PCB-embedded windings, multi-layer planar inductors, and additive manufacturing—offer new opportunities to tailor component geometry, improve thermal integration, reduce parasitics, and enhance performance in ways not possible with traditional winding and core geometries.

However, these techniques introduce non-standard material behaviours, anisotropy, high-frequency parasitics, and reliability challenges. To unlock their full potential, a rigorous assessment of electromagnetic, thermal, mechanical, and manufacturability trade-offs is required. This project provides that foundation, enabling the next generation of ultra-high power-density inductors for multi-MW converters.

Objectives 1

Assess various manufacturing methods (3D printing, embedded magnetics, PCB windings, flat inductors) for magnetic and electrical properties (resistance, HF parasitics, permeability, saturation, anisotropy).

Objectives 2

Investigate new inductor designs with multi-objective optimization considering cost, manufacturability, HF losses, power density, parasitic properties, reliability, and partial discharge in multi-megawatt, HF settings.

Objectives 3

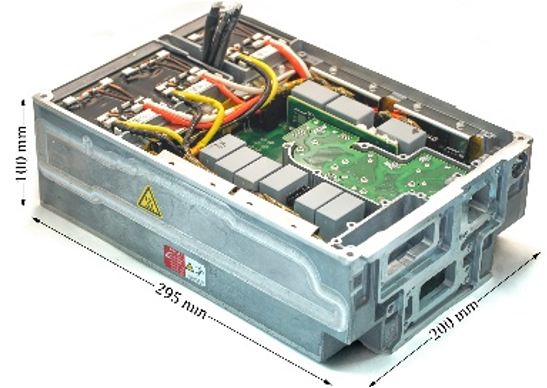

Create high-power-density inductive components using optimal techniques, focusing on integration with multi-megawatt converters, busbar interconnections, and thermal management (air and liquid cooling).

Expected Results

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Phasellus et massa nec arcu efficitur ultrices. Proin laoreet neque eu ligula pretium, vel congue urna faucibus. Integer ut felis dui. Phasellus tincidunt lacus ac ex laoreet, ac ultricies quam condimentum. Vestibulum ante ipsum primis in est.

Sed fringilla gravida lorem, id rhoncus justo egestas sed. Nulla sagittis vel ante sit amet neque non tellus interdum tincidunt eget eu odio. Awesome!