Work Package Description

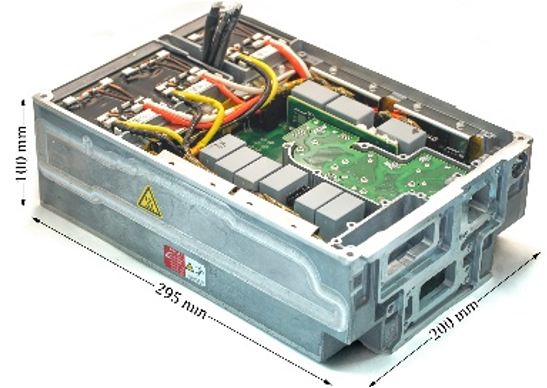

In this activity we need to apply insights from other Work Packages to design, optimise, and manufacture magnetic components for power electronic converters, targeting a minimum of 20% loss reduction and a 15% power-density increase compared to current benchmarks. Prototypes will be developed and tested under realistic operating conditions, with the aim of achieving at least 90% correlation between model predictions and empirical results. Independent validation of the models and components by industry in at least 3 different real-world industrially relevant applications, ensuring a reduction in component size by 15% without compromising performance.

- Easy to use admin panel

- Modern design

- Dedicated tech specialists

- Free 24/7 support

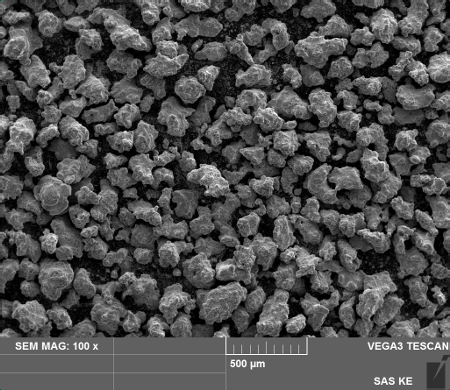

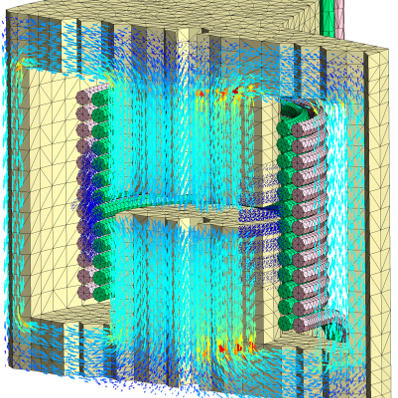

Each of the PhD Candidates involved in this Work Package will adopt a holistic design approach exploiting the novel materials from WP1 and the computational multi-scale, multi-physical models from WP2. DC5, DC7 and DC8 will focus on specific design aspects with a circuit simulator (MATLAB/Simulink). DC5 will develop a new time-domain algorithm to size the inductors of filters accurately the core characteristics, i.e. saturation and losses. DC7 will optimise the converter design accounting for the disparate time constants of the coupled electromagnetic and thermal phenomena in a harmonic balance FE circuit simulator combining dedicated sinusoidal and PWM basis functions. DC8 will aim at optimised winding structures of for transformers in resonant converters in which the leakage inductance is accurately estimated. DC9 will replace linear state-space models in model predictive control algorithms to build up a novel nonlinear controller for grid-connected converters with LCL filters. DC10 will develop innovative integrated filter topologies and magnetic arrangements, enhancing the performance and commercial feasibility of filters in high-power, multi-megawatt electric systems. DC11 will develop high-power density inductive components through exploring and optimizing cutting-edge manufacturing methods, significantly contributing to the efficiency and integration of HF power converters. DC12 will provide novel thermal design methodologies and accurate simulation models for HF magnetic components, optimizing power density and thermal management, thus improving the efficiency and reliability of power electronic systems. DC13 will develop advanced EMC filter designs and simulation models for HF power electronic systems, focusing on efficiency and cost-effectiveness, while addressing differential and common mode current filtering. DC14 will identify and implement optimal insulation methods and materials for high-power magnetic components, balancing power density, compliance with insulation standards, and thermal efficiency. DC15 will develop innovative active cooling solutions and software tools for HF magnetic components, enhancing their power density and thermal performance, particularly for electric transportation applications. The work in this Work Package will contribute to the improved converter designs needed for the resolution of the third Research Objective: Improved converter designs and prototypes.

Research Gaps filled – Novel design workflows for power electronics applications that are both cost-effective and highly accurate in terms of power loss.