Host

Suspendisse tristique vehicula ante tortor, ut auctor diam ornare ut. Pellentesque et ex et dolor tempor suscipit. Phasellus vel orci vel orci tincidunt interdum. Nunc quis viverra metus. In cursus tincidunt. Nam consequat nibh justo, non sollicitudin sem placerat vitae.

Client & task

Suspendisse tristique vehicula ante tortor, ut auctor diam ornare ut. Pellentesque et ex et dolor tempor suscipit. Phasellus vel orci vel orci tincidunt interdum. Nunc quis viverra metus. In cursus tincidunt. Nam consequat nibh justo, non sollicitudin sem placerat vitae.

Objectives

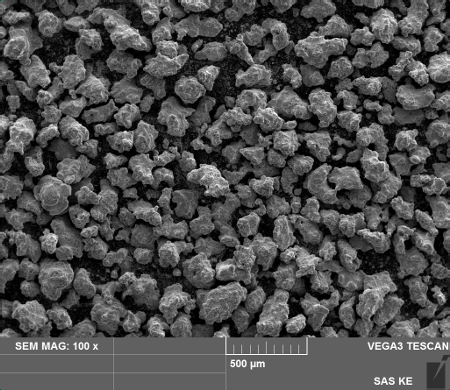

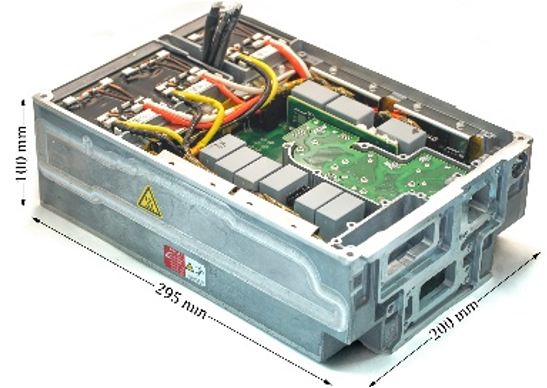

Electrified transportation, aerospace systems, and fast-charging infrastructures increasingly rely on magnetic components that operate at high frequencies and extremely high power densities (>20 kW/kg). At these performance levels, passive cooling becomes insufficient, and components are pushed close to thermal limits, endangering reliability and lifetime.

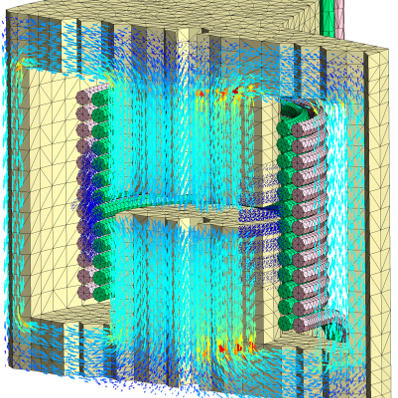

Active cooling technologies—such as heat pipes, micro-channel liquid cooling, spray cooling, or forced-air enhanced convection—enable drastic improvements in thermal performance but introduce complex multi-physics interactions. To fully integrate these techniques, engineers require accurate electro-thermal models, AI-assisted optimisation, and system-level digital twins capable of predicting and managing thermal behaviour under dynamic loads and overload events.

This project delivers these tools, enabling safe, compact, and efficient operation of high-frequency magnetic components in demanding transportation and industrial environments.

Objectives 1

Develop advanced active cooling methods for HF magnetic components in electric transportation, aiming for compact and efficient design using techniques like heat pipes, liquid cooling, and forced air.

Objectives 2

Implement software for electrothermal modelling of these components, using the thermodynamic and power loss ferrite models and results from WP2, capturing the effects of cooling solutions and adaptable to different power levels.

Objectives 3

Design a Digital Twin to monitor and control the thermal performance of these components, optimizing power losses and preparing for overload scenarios, thus improving the component’s design and cost-efficiency.

Expected Results

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Phasellus et massa nec arcu efficitur ultrices. Proin laoreet neque eu ligula pretium, vel congue urna faucibus. Integer ut felis dui. Phasellus tincidunt lacus ac ex laoreet, ac ultricies quam condimentum. Vestibulum ante ipsum primis in est.

Sed fringilla gravida lorem, id rhoncus justo egestas sed. Nulla sagittis vel ante sit amet neque non tellus interdum tincidunt eget eu odio. Awesome!